IBF Series Strainers (Inline Basket Filters)

IBF series fabricated strainers are the ideal solution for removing solid particles from a liquid stream. Applications include protection from debris of pumps, meters, valves, nozzles and heat exchangers.

The IBF series features inline connections, enabling easy pipeline installation. Standard connection sizes are 1” to 12” flanged (ANSI or DN), with bigger vessels available on request.

Fabricated strainers have a bolted lid fitted with a lifting handle and ½” vent valve. Larger models are provided with a davit arm lid lift and can have optional features such as lifting lugs. The standard pressure rating is 10 Bar and temperature rating is 110oc, higher ratings are available on request.

The internal basket has an elliptical, 45o angled top, and provides a high filtration surface area which is vastly superior to cast strainers with the equivalent conection size. The IBF series filters are specifically designed to have high open area ratios (free screen area divided by nominal outlet area), resulting in low pressure drops and longer service before cleaning.

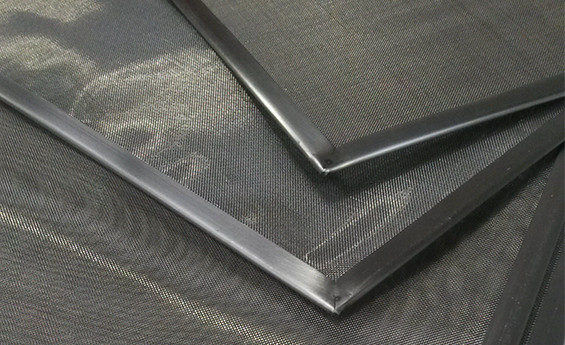

The standard basket is constructed from 3mm perforated sheet, and can be lined with precision woven wire stainless steel meshes ranging from 840 to 37 microns (20 to 400 mesh). For applications requiring coarser filtration, we offer a range of perforated sheet baskets rated from 1mm to 10mm (18 mesh to 3/8”). Other than our standard grades, we are able to provide filter baskets with the option of specified or heavy duty meshes, or manufactured from other materials such as wedge wire.

The standard materials of construction are stainless steel 304 or 316L. The IBF series is customisable to meet specific needs. Options include adjustable or welded leg assemblies, different nozzle types, heating jackets, backflush/backwash system, additional nozzles for gauge ports and many more. Fabricated strainers can be CE marked and provided with ATEX certification on request.

Related Products

-

Bespoke Stainless Steel Mesh Filters

Read moreAllied Filter Systems Ltd manufactures bespoke filters from stainless steel woven wire mesh or perforated plate. Example products include stainless steel mesh panels, filter baskets and discs cut to size. All items are precision manufactured to be dimensionally accurate and can be produced in small volumes as well as in larger batches. Finished articles range in size from just a few centimetres to several metres.

-

IBF Series Strainers (Inline Basket Filters)

Read moreIBF series fabricated strainers are the ideal solution for removing solid particles from a liquid stream. Applications include protection from debris of pumps, meters, valves, nozzles and heat exchangers. The IBF series features inline connections, enabling easy pipeline installation. Standard connection sizes are 1” to 12” flanged (ANSI or DN), with bigger vessels available on request. Fabricated strainers have a bolted lid fitted with a lifting handle and ½” vent valve.

-

Simplex and Duplex Basket Filters

Read moreSimplex fabricated basket filters are designed for applications where temporary interruption of a process can be permitted for basket cleaning. They feature a recessed basket with lifting handle, seated on an internal ring. An under basket o-ring is present to ensure an excellent seal between the filter housing and basket. Simplex basket filters are bolted lid, side entry vessels, with either a bottom or side outlet (Styles 2-8).Fabricated basket filters can also be duplexed to enable continuous operation.