Wound Filter Cartridges

Wound filter cartridges are economical, nominal rated depth filters. They are produced from a continuous fibre yarn spirally wound around a central support core.

The computer controlled winding pattern ensures precise, reliable and repeatable particle removal performance. Wound filters feature a graded density construction, enabling progressively smaller particles to be captured through the depth of the filter media. The result is a high dirt holding capacity filter which has a low pressure drop.

Wound filter cartridges are most commonly made from polypropylene yarn wound on to a polypropylene core, but for applications where chemical compatibility or operating temperature restricts the use of polypropylene, other fibres such as cotton, glass, polyester, nylon or polyphenylene sulphide (Ryton) can be offered wound on to a stainless steel core. We also offer the option of a glass reinforced polypropylene core which provides superior strength and permits higher operating temperatures (up to 100oC)

- Available in a wide range of micron sizes from 0.5 – 150.

- Standard length: 4 7/8” to 40”.

- Custom lengths up to 60” possible.

- Standard diameter: I.D. 27.5mm, O.D. 62mm.

- Available in large 110mm diameter, 10″ and 20″ lengths for higher flow rates and dirt holding capacity.

- Most commonly double open ended, but can be fitted with all industry standard end caps.

- O-rings for end caps include Nitrile, EPDM, Silicone, Viton, PTFE encapsulated Viton, PTFE encapsulated Silicone.

- Washed or fibrillated polypropylene also available for sensitive applications.

- Maximum recommended differential pressure : 2.5 Bar

Please contact us for further information or view our range of Filter Cartridges.

Related Products

-

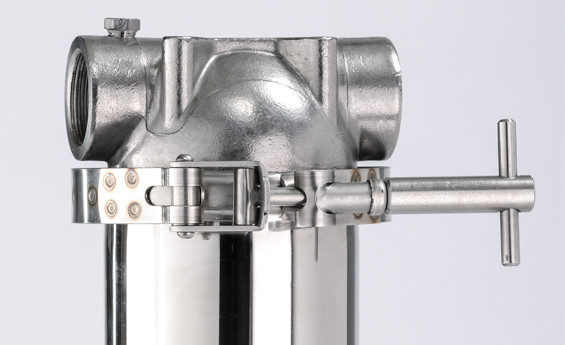

LV1 Stainless Steel Single Cartridge Housings

Read moreThe LV1 series single cartridge vessels consist of an investment cast head with 1” BSP (F) inline connections and 1/8” BSP (F) vent, a quick release clamp, and a bowl with ¼” BSP (F) bottom drain. LV1 vessels are produced in four sizes to suit industry standard 10”, 20”, 30” and 40” nominal length filter cartridges. The universal head can be configured to suit various cartridge end caps.

-

Multi Round Stainless Steel Cartridge Housings

Read moreMulti round cartridge vessels feature a universal bottom cup to suit double open ended, code 8 (222 o rings/fin) or code 3 (222 o rings / flat) cartridges. Our vessel design therefore provides versatility – by simply exchanging the cartridge top sealing components, the vessel can be converted to suit a variety of cartridges.

-

Plastic Cartridge Housings

Read morePlastic Cartridge Housings – For applications involving non-aggressive fluids, these are a low cost, small sized single cartridge housings to suit 10″ or 20″ cartridges.